Types of polishing fiber optic connectors

Polishing task — ensure installation feedthrough connectors in the absence of an air gap between the ends of the fibers, i.e., in fact, to ensure physical contact of the fibers, to reduce signal back reflection (reflectance).

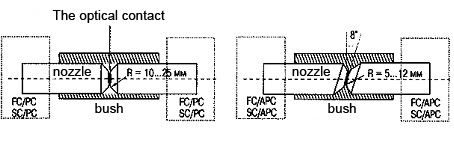

Scheme of the optical contact at the connection terminals PC and APC connectors.

Currently distinguish 4 class polishing: PC, SPC, UPC and APC.

Polishing PC — the name really stands for Physical Contact, physical contact — and at first there was the first version included a flat tip. Experience has shown that the connector is a flat end can not avoid the formation of air gaps between the ends of optical fibers, and this in turn leads to a rather large reverse reflections, which is undesirable. Therefore, the ends of the lugs purchased rounding. These have now rounded and connectors ST, and SC, and FC, and some other less common. For example, the modern terminals have ST ceramic ferrule (ferrule) diameter of 2.5 mm, the radius of curvature of the mechanical approximately 20 mm. FC connectors in this very similar to the connectors ST, but instead they use a bayonet connector fitting. This class will include all bandaged hand and zapolirovat modern connectors, manufactured by adhesive technology. They are suitable for most communication systems, where it is a short distance and not too demanding applications. This is primarily structured cabling systems and small computer networks.

Since polishing PC as a whole does not give perfect results (typical insertion loss for single-mode fiber — 0.2 dB reflectivity in the range -35 dB), the producers continued to search for new methods of polishing, and so there were types of APC (Angled Physical Contact) and SPC ( Super Physical Contact). The main difference of APC connectors is that the fiber end zapolirovat angle (typically 8 degrees), and this allows to achieve much better results. Due to this, almost all of the reflected angle (unwanted) signal leaves the fiber. APC connectors with other types of connectors are not compatible, so the color-coding is green. Better than connectors APC, yet nothing came up, reflectivity, and could reach -60 dB and -65 dB — that is reflected back less than one ten-thousandth of a signal — so they are used to implement the most demanding applications, such as the transmission of analog video in the provider’s backbone communication lines etc. Patch in the field such connectors is extremely difficult, almost impossible, so their destiny — pre-assembled.

Polishing SPC (Super Physical Contact), in contrast, does not use any angle differs from a conventional PC polishing only higher quality. The end of the fiber is polished normal way, instead of just hand polishing machine is used. So, if you buy a one-way fiber optic jumpers (Pigtails), which will okontsovyvat padded segment by welding, it is likely that these Pigtails are polished connectors with SPC. They are better than manually embedded connectors, and have a reflectivity of between -40 dB. Basically, if you have the right equipment, you can achieve these characteristics and their own, but it can not be called «normal field conditions»: in fact, you’re at the factory recreate conditions just on a smaller scale.

The final version appeared polishing UPC (Ultra Physical Contact), and also the development ideas conventional connector, without the use of polishing angle, but with the use of specific engine technologies, including the radius of curvature of the tip. This option allows for polishing reflectivity at -55 dB, which is slightly worse than the APC, but it is better than the alternatives polishing. First of all it is important for single-mode connectors. Also, this version of polishing is used by manufacturers of optical measuring equipment. Types of polishing PC, SPC and UPC are compatible with each other, because all of them are not talking about polishing at an angle. Of this group the most UPC gives good characteristics, so that it is best used in the form of optical instruments — for example, reflectometers, active high speed optical equipment, etc. Naturally, in the field to achieve such performance can not be so, if these connectors meet you and then only as part of the purchased optical patch cord or Pigtail.